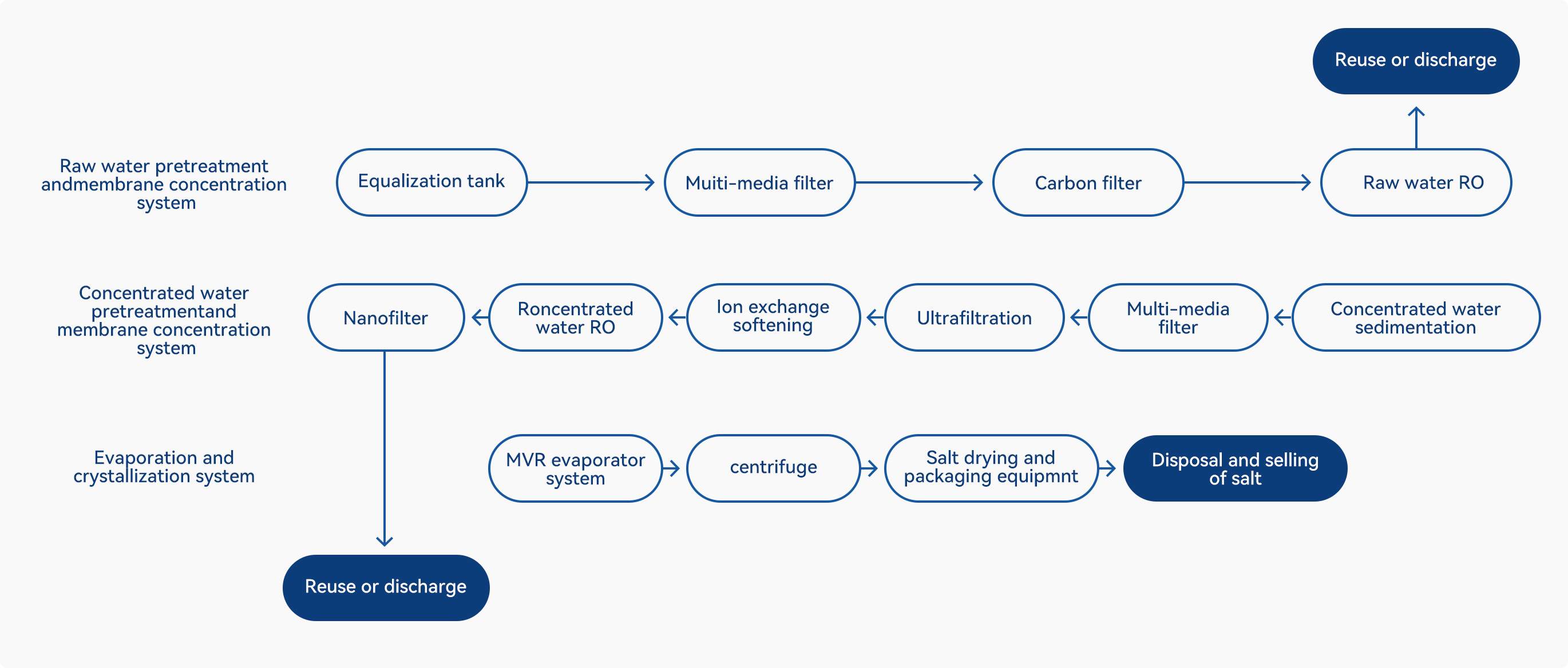

Balances incoming water quality and quantity, reducing the impact of water quality and quantity fluctuations on subsequent treatment processes. It also provides initial sedimentation and buffering, ensuring stable system operation.

Multi-media filtration removes suspended solids, turbidity, and some organic matter. Activated carbon filtration further removes color, odor, and adsorbable organic contaminants, providing stable water quality for membrane system operation.

Efficiently removes dissolved salts, heavy metals, and most organic matter, producing clean water that meets process requirements while also concentrating salts and impurities in wastewater.

Chemical agents or softening devices are used to remove calcium and magnesium ions from the water, reducing hardness, preventing scaling in subsequent membrane equipment and evaporation systems, and extending equipment life.

Removes colloids, bacteria, and large organic molecules, ensuring safety for subsequent reverse osmosis of concentrated water, ensuring low turbidity and SDI values in the RO feedwater, and improving membrane system operational stability.

Further removes residual hardness, specific ions, or trace impurities. As a deep finishing unit, it ensures high-purity water or specific process water quality requirements.

Re-desalinates and reduces the brine produced by the raw water RO process, improving the overall system's water recovery rate and reducing wastewater discharge.

Selectively separates divalent and monovalent salts, enabling salt resource diversion and facilitating subsequent crystallization and comprehensive salt utilization.

Utilizes mechanical vapor recompression technology to evaporate, concentrate, and crystallize high-salinity wastewater, achieving zero wastewater discharge while simultaneously recovering clean condensate.

The industrial salt produced by crystallization is collected and sold, transforming the by product into a resource, reducing solid waste disposal and generating economic benefits for the project.

◎ 2025 Beijing Bianhuadian Chemical Analytical Instruments Co., Ltd.. All Rights Reserved.