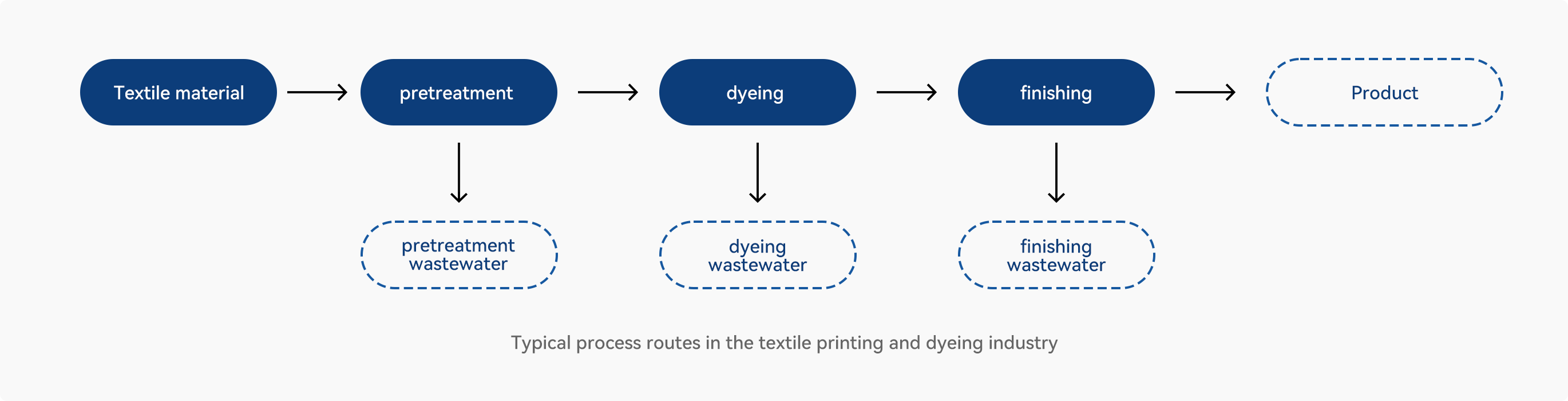

Pre-treatment wastewater is mainly divided into:

Pre-treatment wastewater mainly from cotton printing and dyeing, mainly from desizing, scouring, bleaching and mercerizing;

Pre-treatment wastewater mainly from chemical fiber printing and dyeing, mainly from oilremoval, refning and alkali reduction;

Pre-treatment wastewater mainly from silk printing and dyeing, mainly from cocoon boling, sik reeling and scouringd

Pre-treatment wastewater mainly from hemp printing and dyeing, mainly from degumming,

Pre-treatment wastewater mainly from wool spinning and dyeing comes mainly from wool washing and carbonization

Dyeing/printing wastewater is mainly dyeing wastewater or printing wastewater.

Finishing wastewater mainly refers to washing wastewater generated by finishing treatment.

Other wastewater mainly includes domestic sewage, part of the discharged circulating condensate water and ground washing water, etc.

Deep treatment and reuse treatment process

The deep treatment or reuse treatment process and technical parameters should be determined according to the water quality, discharge standards or reuse requirements through process tests and technical and economic comparison. The selection of deep treatment or reuse treatment process should be considered in combination with conventional treatment units.

The deep treatment or reuse treatment process after conventional treatment can generally adopt one or a combination of processes such as coagulation sedimentation (or flotation), chemical oxidation, membrane separation, membrane bioreactor (MBR), aerated biological filter, biological activated carbon, filtration, adsorption, etc.

The high-salt water produced by membrane separation can be properly treated by concentration, evaporation and other methods.

◎ 2025 Beijing Bianhuadian Chemical Analytical Instruments Co., Ltd.. All Rights Reserved.