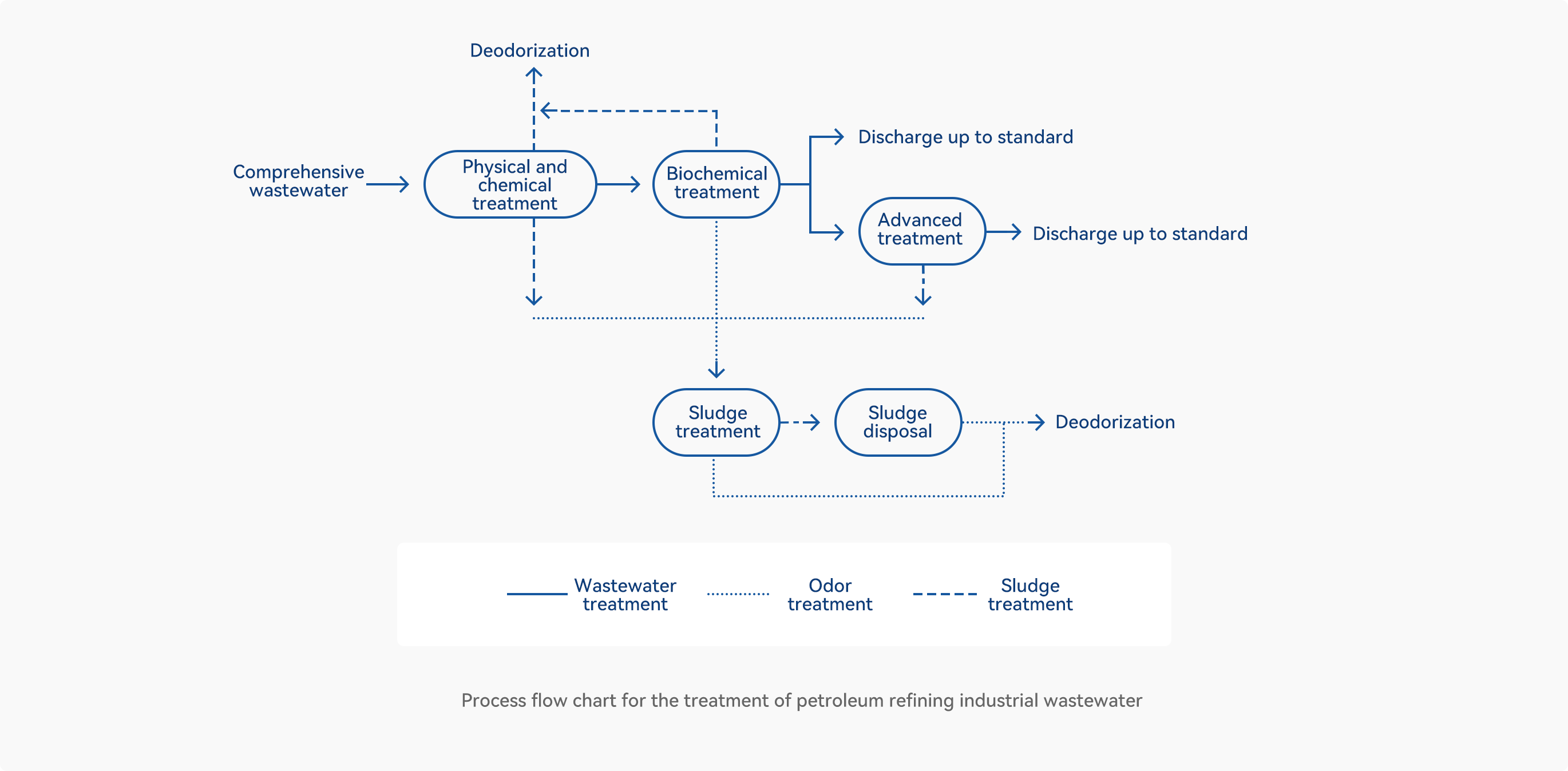

Process flow chart for the treatment of petroleum refining industrial wastewater

The recommended processes for process units are shown in Table 3, and the recommendations are not limited to the following processes.

| Process unit | Recommended process |

|---|---|

| Physical and chemical treatment | Equalization tank (pool) → Oil separation tank → Neutralization tank → Homogenization tank → Coagulation air flotation tank |

| Biochemical treatment | Process 1: Biochemical tank → Secondary sedimentation tank |

| Process 2: Hydrolysis acidification tank → Biochemical tank → Secondary sedimentation tank | |

| Process 3: Hydrolysis acidification tank → CAST process → Hydrolysis acidification tank → A/O biochemical tank → Secondary sedimentation tank | |

| Process 4: A/O or A/O/O biochemical tank (powdered activated carbon added to the tank) → Secondary sedimentation tank | |

| Process 5: Oxidation ditch → Secondary sedimentation tank | |

| Advanced treatment | Process 1: Tertiary turbidity removal → Monitoring tank |

| Process 2: The secondary sedimentation tank in the biochemical treatment section is cancelled, and the MBR method is used for monitoring and external discharge. | |

| Process 3: Tertiary turbidity removal → Filter tank (pool) → Ozone advanced oxidation tank → Aerobic biological filter, etc. → Monitoring tank | |

|

Note 1: For refineries with a low proportion of inferior heavy oil processed, biochemical treatment process 1 is recommended; for refineries with a high proportion of inferior heavy oil processed, when oily and saline wastewater is mixed for biochemical treatment, biochemical treatment processes 2, 3, and 4 are recommended; when oily and saline wastewater is treated separately, biochemical treatment process 2 is recommended in the oily wastewater treatment system, and biochemical treatment processes 3, 4, and 5 are recommended in the saline wastewater treatment system. Note 2: In biochemical treatment processes 1 and 2, the biochemical tank can adopt A/O, A/O/O or sequential batch activated sludge process and the mud-membrane hybrid process derived on this basis. Note 3: The process route of advanced treatment should be selected according to the specific indicators of the wastewater discharge standard. |

|

The technical route for the treatment of coking wastewater should be selected according to the following principles:

(1)Single physical and chemical treatment: such as wastewater incineration, salt extraction from desulfurization waste liquid or acid production, etc.

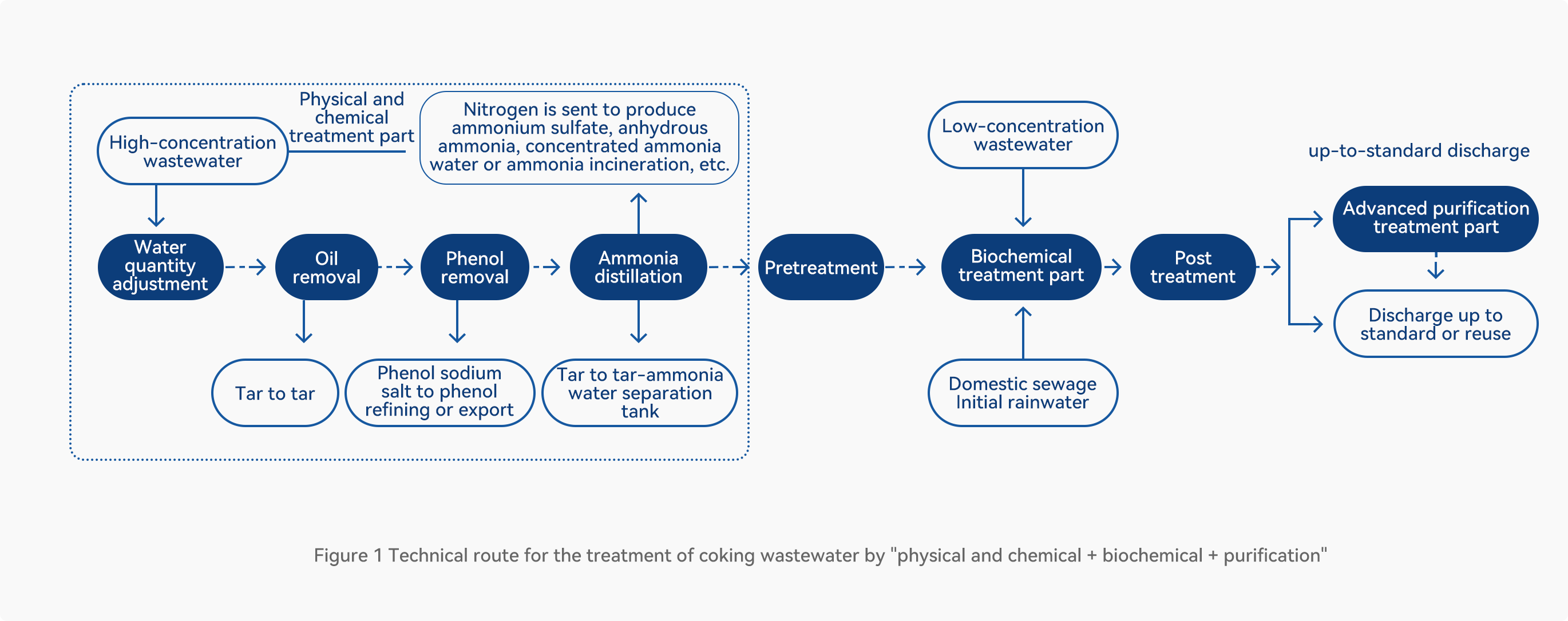

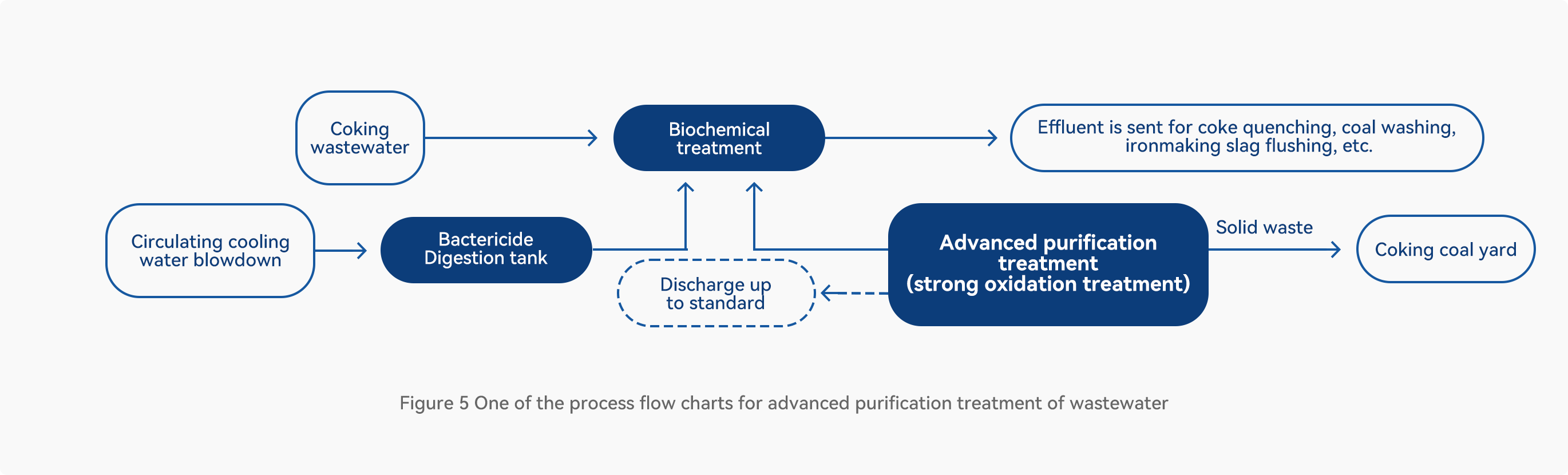

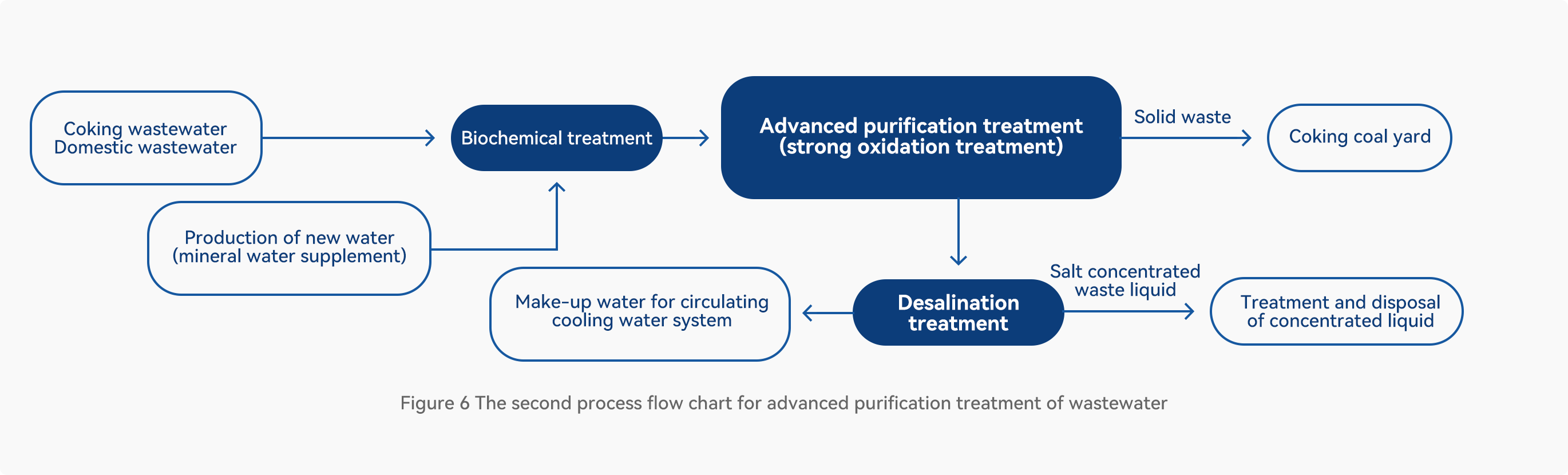

(2)The combined treatment process of "physical and chemical treatment + pretreatment + biochemical treatment + post-treatment + advanced purification treatment" should give priority to the technical route in Figure 1 according to different production objects and wastewater quality:

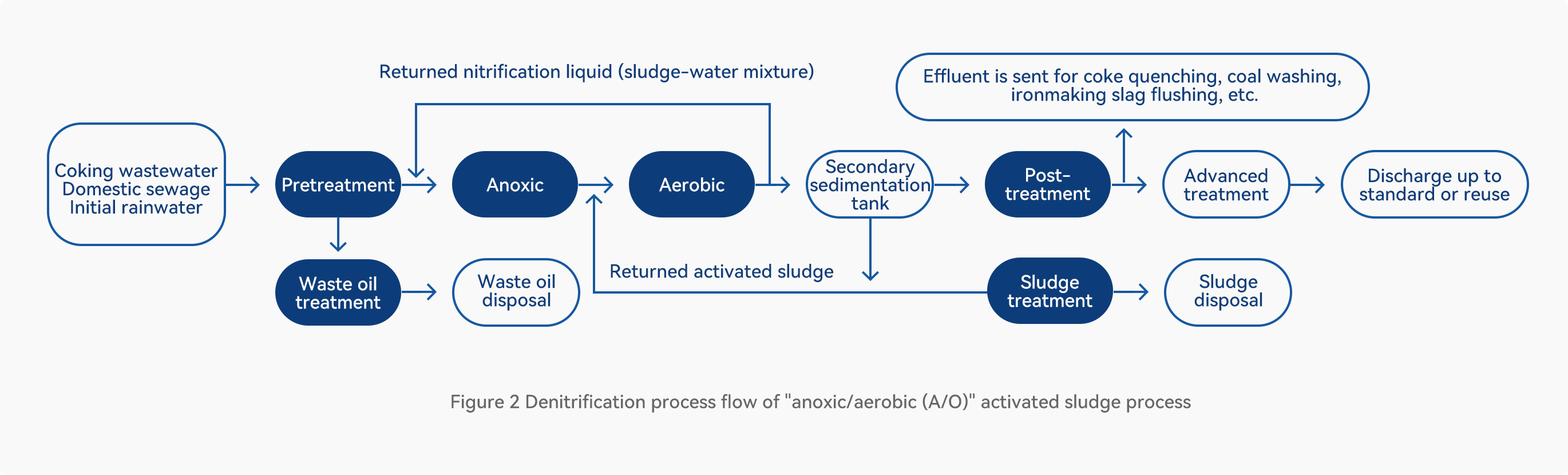

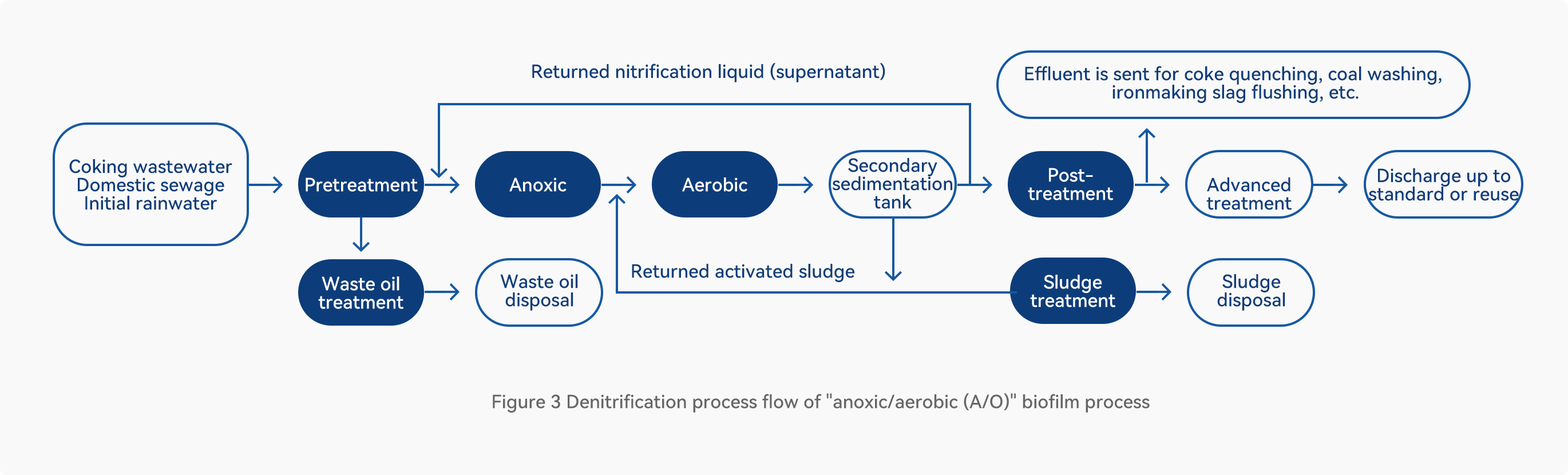

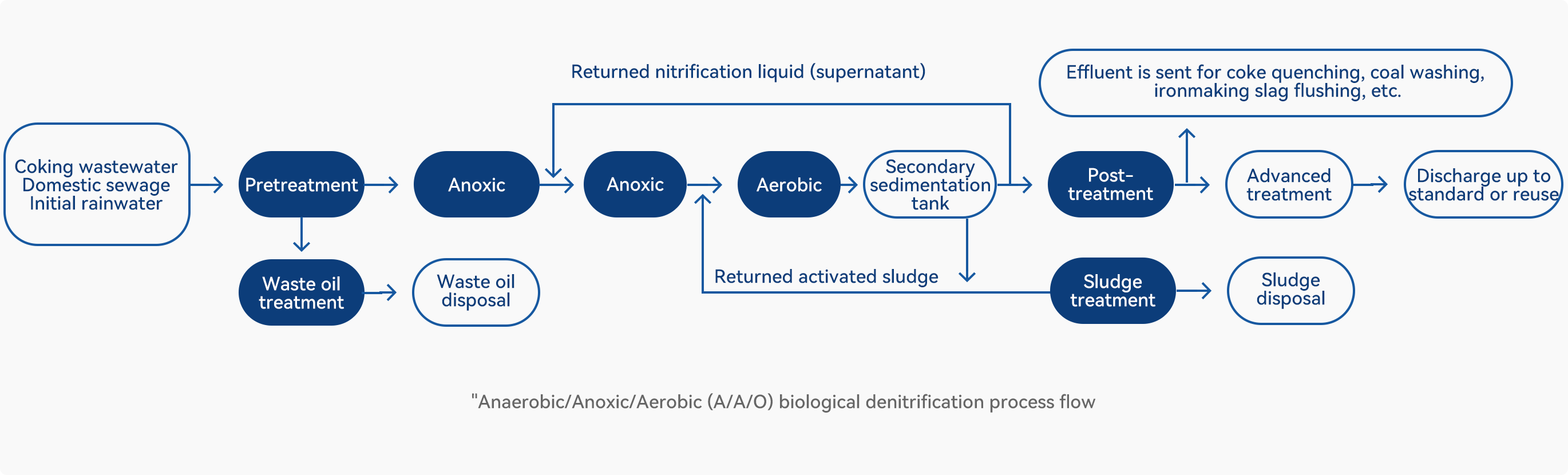

The biochemical treatment of coking wastewater should include the basic denitrification process of "anoxic denitrification/aerobic nitrification", and the processes recommended in Figures 2 to 4 should be preferred.

◎ 2025 Beijing Bianhuadian Chemical Analytical Instruments Co., Ltd.. All Rights Reserved.